Technology

Principle of Operation & Technical Documents

Cavity Ring-Down Spectroscopy (CRDS)

Detection at the Speed of Light

Based on absorption spectroscopy, Cavity Ring-Down Spectroscopy (CRDS) works by attuning light rays to the unique molecular fingerprint of the sample species. By measuring the time it takes the light to fade or "ring-down", you receive an accurate molecular count in milliseconds. The time of light decay, in essence, provides an exact, non-invasive, and rapid means to detect contaminants in the air, in gases, and even in the breath.

A breakthrough discovery by Professor Kevin Lehmann, Ph.D., of Princeton University made the commercialization of this technique possible. He proved that compact, relatively inexpensive, and widely available Continuous Wave (CW) lasers can substitute for the costly, cumbersome pulsed lasers previously used in CRDS-based research. He thereby made the requisite power of light affordable and practical for commercial use.

How It Works:

- A Continuous Wave (CW) diode laser emits a directed beam of light energy through an ultra-high reflective mirror into the absorption cell (cavity).

- The light reflects back and forth between two ultra-high reflective mirrors multiple times, up to a total path length of 100 kilometers.

- Once the photodiode detector “sees” a preset level of light energy, the light source is shuttered or diverted from the cavity.

- On each successive pass, a small amount of light or ring-down signal emits through the second mirror and is sensed by the light detector.

- Once the light "rings down", the detector achieves a point of zero light energy in milliseconds, and the measurement is complete.

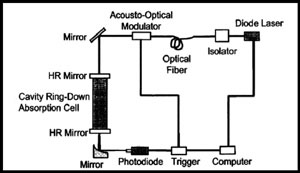

CRDS Schematic

The key components illustrated are as follows:

- Diode laser: Emits light energy

- Isolator: Prevents light energy feed-back from interfering with the laser Acousto-Optical

- Modulator: Shuttering device for the light source

- Absorption Cell: With mirrors, creates measure-ment cavity

- Photodiode: Monitors the light energy from the absorption cell

- Trigger: Works in concert with the photo-diode and sends signal to the AOM to activate the ring-down cycle.

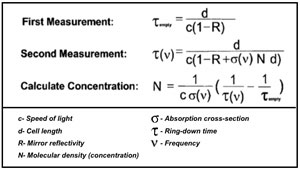

Principle of CRDS

- The computer-controlled system tunes the laser off the absorption peak for the sample species to determine the τ empty value, equivalent to a zero baseline correction.

- It tunes back to the absorption peak to determine the τ value, dependent on the sample species concentration.

- The concentration of the sample species is directly calculated using the above equations.

- Based on Beer’s Law, this value constitutes an absolute measurement and is unaffected by losses outside the ring-down cavity.

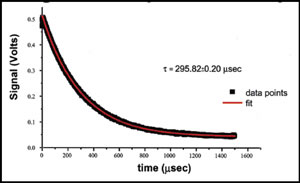

Ring Down/ Exponential Decay

This graph depicts the concept of ring-down decay within the cavity after the laser source is shuttered. As the laser light bounces back and forth between the ultra-high reflective mirrors, the sample species absorbs the light energy until it’s all gone.